A Review: Technologies for the Preparation of Plant-derived Salty Peptides and Their Application

-

摘要: 咸味肽作为一种新型的食盐替代物,在食品减盐方面有着至关重要的作用,尤其是需要低钠食品的特殊人群,具有广泛的应用前景。因此,咸味肽的制备和开发成为当前的研究重点。本文以植物源咸味肽为对象,分别对咸味肽的研究必要性及结构特点、ENaC等咸味受体与咸味肽的作用机制、咸味肽结构与呈味特性的构效关系,以及咸味肽分离纯化鉴定技术及在咸味香精、增咸烹饪盐和咸味增强剂等应用等方面进行综述。为促进植物源咸味肽的深入机理研究及产品开发提供理论依据。Abstract: Salty peptides play vital roles in salt reduction of food as novel salt substitutes, especially for special people who need low-sodium food, and have a wide application prospect. Therefore, the preparation and development of salty peptides have become the focus of current research. In present review, plant-derived salty peptides are taken as the target, research necessity and structural characteristics, the mechanism of action of salty taste receptors such as ENaC, the structure-activity relationship between the structure and taste characteristics of salty peptides, the preparation technology, the separation, purification and identification technology, the application of plant-derived salty peptides are summarized, such as savory flavors, saltiness-enhanced cooking salt and savory enhancers. The review would lay a theoretical basis for promoting the mechanism research in depth and product development of plant-derived salty peptides.

-

咸味作为人类不可或缺的基本味之一,是人类感知食物风味的重要基础[1],但长时间食用盐过度摄入会引发高血压等心血管疾病[2]。为贯彻落实《“健康中国2030”规划纲要》,许多食盐替代物出现在大众的视野中,如非钠盐、咸味肽、咸味增强肽及风味改良剂等。非钠盐是指与食用盐性质相似,可以呈现咸味的金属盐类[3],但其只能降低食品中部分钠含量,限制了在食品中的应用。风味改良剂可以弥补减盐导致的咸味下降[4],但需要与其他代盐剂结合使用。咸味肽是一种较为理想的食盐代替物[5],不仅能够满足人类对口味的需求,还可补充人体所需氨基酸,可以真正做到“减盐不减咸”。

咸味肽是指通过酶解等工序对富含蛋白质的原料进行提取、由氨基酸组成的、呈咸味的活性多肽[6]。按食物来源可分为动物源、植物源和酵母源等,其中植物源咸味肽是源于植物蛋白的多肽,可应用于食品减盐领域,具有安全性高、应用范围广等优点,是一种极具潜力的食源性活性肽[7]。为拓展植物源咸味肽的研究现状,本文综述了植物源咸味肽的呈味机理、制备技术、分离鉴定技术,并概述了植物源咸味肽的应用,为进一步促进植物源咸味肽的深入研究和食品研发提供理论依据和参考。

1. 咸味肽的研究必要性及结构特点

1.1 咸味肽开发应用的必要性

2022版膳食指南将食盐推荐摄入量调整为小于5 g,但目前中国人均每日食盐摄入量为9.3 g[8],因此减盐成为未来食品科技领域的热点。研究表明,长期高钠摄入会提高高血压等心血管疾病的发病率[9]。因此,开发既能满足人体对咸味的需求,同时又能降低钠离子摄入的食盐代替物是非常必要的。咸味肽不仅可以提高人体对咸味的感知,且大部分咸味肽还具有功能特性,是未来食盐代替物发展的必然趋势。Tada等[10]第一次在酪蛋白水解物中提取出咸味二肽Orn-β-Ala,其咸味强度与NaCl相当。国内学者对郫县豆瓣酱发酵过程中产生的呈味肽进行分离和鉴定,结果表明其中有六种肽具有咸味或者咸味增强作用[11]。对豌豆蛋白进行深度酶解,所获得的小分子肽具有较明显的咸味[12]。从中国商业发酵豆渣中分离出4种呈味肽,其中EDGEQPRPF具有咸味和增强咸味的作用[13]。不同原料来源的咸味肽咸度及氨基酸序列的差异,导致其在食品中的应用各不相同,动物源咸味肽如从鱼虾中提取的咸味肽制成的产品,海鲜过敏的人群不能食用。以植物为原料制成的咸味肽应用范围广,可以更好地被人体消化利用。由此可见,开发植物源咸味肽产品尤为重要。

1.2 咸味肽结构特性

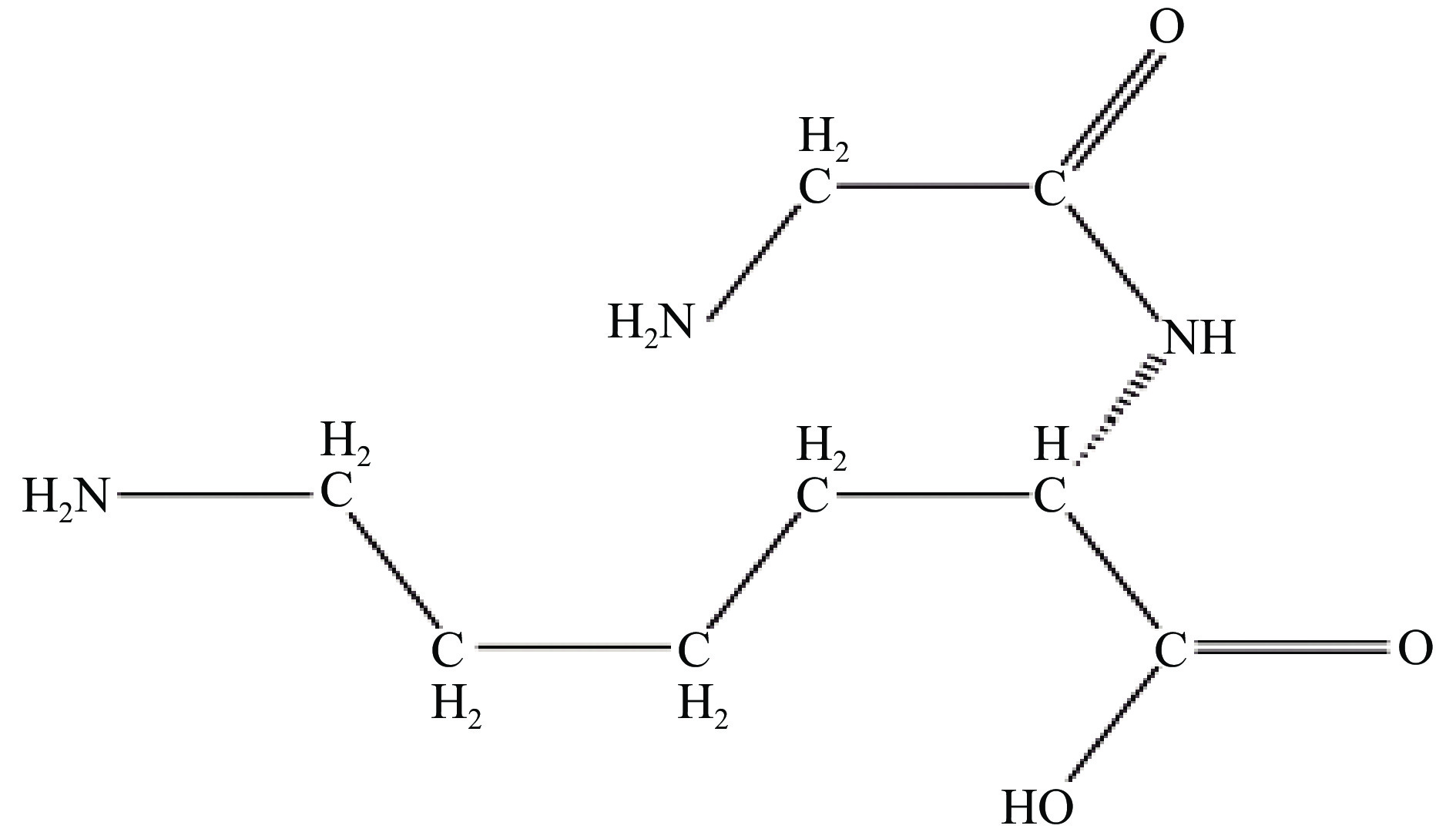

天然存在的氨基酸分为L型和D型。L型氨基酸及其盐类大部分呈苦味、甜味,少部分呈咸味、鲜味和酸味,而D型氨基酸大多呈甜味[14]。咸味肽主要由2个及2个以上的L型氨基酸组成,咸味二肽结构图见图1[15]。

2. 咸味肽受体与机制

2.1 咸味肽受体通路

目前,研究发现咸味受体包括瞬时受体电位香草酸亚基(TRPV1)和上皮钠离子通道(ENaCs)两种[16]。当Na+在口腔中达到一定浓度时,会刺激ENaCs并感受咸味。TRPV1不仅对Na+敏感,还对其他离子如K+和Ca2+等敏感。ENaCs由α、β和γ等3种亚基组成异源三聚体通道(图2),α亚基主要负责Na+进出细胞,β亚基调控Na+转运的速度,γ亚基负责剪切ENaCs的特定位点而调节其活性[17]。TRPV1是介导Ca2+和Na+等单价和二价阳离子的一类跨细胞膜非选择性阳离子通道,TRPV1通道开放后可产生Na+内流,通过介导细胞内Na+浓度来对咸味感受进行调控[18]。总之,两者皆为咸味传感受体,中低盐浓度可以依靠ENaCs来感受咸味,而高盐浓度可以通过刺激TRPV1来感受咸味。咸味肽主要靠激活ENaCs表达咸味。Anand等[19]证实半胱氨酸和丝氨酸可以作为通道激活蛋白,协助Na+刺激ENaC受体。

2.2 咸味感受机制

味蕾是位于口腔上皮的感受器官。咸味物质与味蕾中味觉感受器细胞中的受体进行特异性结合,通过味觉神经传递,最后由大脑中的味觉中枢表达[20]。咸味肽的呈味机理不仅与受体的特异性结合有关,还与咸味肽的解离程度和所含特殊阳离子有关。咸味肽呈味的关键在于咸味肽电离出阳离子后,阳离子刺激处于细胞膜上的ENaCs通道后发生相互作用,进而使Ca2+极化。当细胞的内部带正电时,咸味传感受体释放特定的味觉神经介质,通过舌后部的舌咽神经传递到脑干并感受咸味[21]。

3. 咸味肽的构效关系

咸味肽的呈味特性与其相对分子质量、氨基酸组成、氨基酸序列和空间结构等密切相关。

3.1 咸味肽相对分子质量

咸味肽是一种小分子肽,分子量通常小于1000 Da。刘平等[22]考察分子量不同的五种大豆肽的美拉德反应产物对鸡汤风味的影响,结果表明小于1000 Da的大豆肽呈现了较好的咸味增强效果,表现出明显的咸味和鲜味[23]。研究表明,当分子量小于1000 Da时,咸味肽的咸味表现能力最强。因此,在开发应用咸味肽时,应以相对分子量质量较小的肽类为主。

3.2 咸味肽氨基酸组成及序列

目前发现的咸味肽主要为咸味二肽和咸味三肽,大部分都与谷氨酸、天冬氨酸片段有关。部分咸味肽来源与结构式见表1。

表 1 咸味肽来源与结构式Table 1. Origin and structural formula of salty peptides类型 来源 咸味肽序列 参考文献 咸味二肽 大豆种子蛋白 Glu-Tyr,Glu-Phe [24] 大豆蛋白 Val-Gly [25] 大豆蛋白 Glu-Tyr,Glu-Phe [26] 豆瓣酱提取物 Glu-His,Glu-Trp,Glu-Leu,Glu-Met,Glu-Val,Glu-Gln,Glu-Phe [27] 味增提取物 Glu-Val [28] 可可豆蛋白 Tyr-Val [29] 咸味多肽 大豆蛋白 Glu-Val-Gly [25] 酱油提取物 Ser-Pro-Gln,Gln-Gly-Ile,His-Asn-Pro,Lys-Gly-Cys [30] 酱油提取物 Gly-Gly-Gly-Gly,Glu-Gln-Gln-Gln-Gln [31] 酱油提取物 Glu-Ala-Gly-Ile-Gln [32] 3.3 咸味肽的空间结构

当咸味肽含3个氨基酸以上,必须考虑其空间结构[33]。肽链长度的不同会造成空间结构和电荷分布的不同,另外咸味肽结构中羰基、羧基及酸性氨基酸的存在会导致咸味肽一级结构不能解释和预测咸味肽结构和呈味特性的关系。但目前关于咸味肽空间结构与呈味特性的研究相对较少。

综上所述,咸味肽的呈味特性与氨基酸的相对分子质量、组成、序列及空间结构有关,研究咸味肽从咸味肽的构效关系中入手,可以较好的开发咸味肽及其产品。

4. 植物源咸味肽的制备与合成方法

植物源咸味肽的制备方法主要有化学水解法[34]、酶水解法[35]、生物工程法[36]和微生物发酵法[37];合成方法包括化学合成法中的固相合成法和液相合成方法[38]。制备方法中比较常用的有酶解法及微生物发酵法,化学合成法也被广泛应用于咸味肽的合成中。植物源咸味肽的各种制备方法见表2。

4.1 天然植物源咸味肽的制备

4.1.1 化学水解法

化学水解法分为酸水解法和碱水解法。在酸性或碱性的条件下,蛋白质可以发生反应,产生氨基酸[39]。Jeon等[40]向韩国大酱汤中添加经过酸水解的植物蛋白,结果表明酸水解后的植物蛋白具有明显的增咸作用。蛋白质的化学水解法具有提取快速及彻底的优点,但是时间和水解温度不易控制,并且会引起消旋作用,破坏敏感氨基酸。因此,化学水解法较少应用于生产。

4.1.2 酶水解法

酶水解法是指使用单个或复合蛋白酶在最适条件下水解蛋白质,并获得具有呈味效果的功能肽[41]。使用酶水解后的植物蛋白与还原糖混合制备美拉德反应产物,其产物具有明显的咸味和咸味增强作用[42]。酶水解法具有稳定性好、操作方便、过程可控、专一性强等优点,特别在制备咸味肽方面,可以最大保留咸味肽的风味及营养。因此,酶水解法为制备植物源咸味肽最常用、最安全的方法,被广泛应用于植物源咸味肽的制备。

4.1.3 生物工程法

生物工程法是指对植物基因组分的DNA片段进行分离,而后此DNA片段被克隆到适宜的载体,并导入受体细胞,通过细胞表达得到咸味肽[43]。已有报道证实,可采用生物工程法制备咸味二肽Gly-Asp[44]。该方法具有原料价格低廉、咸味肽产率高以及特异性高等优点,但在DNA重组过程中对灭菌的要求较为严格,并未得到广泛的应用。

4.1.4 微生物发酵法

微生物发酵法是指利用微生物发酵蛋白质底物从而来生产咸味肽的方法[45]。Suzuki等[25]利用地衣芽孢杆菌对大豆蛋白进行发酵,所得的产物经过γ-谷氨酰转肽酶转化后具有明显的咸味增强作用。该方法不需要使用化学试剂,使用的菌种易培养,培养周期短,而且发酵过程还可以去除底物中存在的高过敏性因子及抗营养因子。但不同的菌种差异较大、发酵过程难以控制等缺点在应用中仍存在限制,有待进一步开发。

4.2 植物源咸味肽的化学合成

化学合成法是指通过氨基酸的缩合反应形成酰胺键来合成咸味肽,主要有液相合成法和固相合成法[46]。目前化学合成法仍为合成呈味肽的首选方法,因为此方法可以合成大量的所需目标肽。

4.2.1 液相合成法

液相合成法作为最早应用于多肽合成的方法,主要分为逐步偶联反应和肽段偶联反应[47]。逐步偶联反应是将多肽链的C端逐步与氨基酸连接直到整个多肽链完成。肽段偶联反应大多先合成各个所需片段,再将各个所需片段合成目标肽[48]。液相合成法具有成本相对较低、中间产物可以优化等优点,主要用于合成长肽链。因咸味肽大部分为二肽或者三肽,液相合成法并未广泛应用在咸味肽的合成中。

4.2.2 固相合成法

固相合成法是指以共价键的方式将肽链末端的羟基与高分子树脂连接,氨基酸通过缩合反应将脱保护的N端与第二个氨基酸的活化羧基结合,进行缩合,洗脱,再缩合的重复操作,从而达到目标肽的长度,而后从高分子树脂上裂解下来,分离后纯化,最后获得目标多肽[49]。固相合成法可以根据α-氨基酸保护基不同,可分为Boc法和Fmoc法。Feng等[50]通过固相合成法合成Gly-Leu-Pro-Asp和Gly-His-Gly-Asp两种咸味肽并添加到鸡肉汤中,可以显著增强鸡肉汤的咸味和鲜味。对比液相合成法,固相合成法操作简便,技术成熟,合成的多肽纯度较高。目前,固相合成法被广泛用于多肽的合成中。

5. 植物源咸味肽分离纯化与鉴定技术

5.1 植物源咸味肽分离纯化技术

植物源咸味肽的分离纯化通常采用超滤技术、凝胶过滤色谱技术以及高效液相色谱技术等。但只使用一种分离纯化技术很难获得较为纯净的植物源咸味肽,一般采用多种分离纯化技术联用。

5.1.1 超滤技术

超滤技术是指将溶液中的物质通过不同孔径的超滤膜而逐步达到分离纯化及浓缩的技术手段[51]。超滤技术作为一种快速、经济和环保的技术手段,其原理是利用空气压力使物质溶液穿透超滤膜,小于孔径的小分子物质透过超滤膜被收集,大于孔径的大分子物质被截留在超滤膜上,从而完成物质溶液的分离纯化,常用于>10 kDa、5~10 kDa、3~5 kDa、1~3 kDa及<1 kDa分子量肽段的分离[52],结合其他分离纯化技术联用得到单一纯化的肽。Kong等[53]利用超滤技术与其他技术联合使用,成功从大豆种子水解物中分离出咸味肽,该咸味肽可作为味觉增强剂添加到食品中。

5.1.2 凝胶过滤色谱技术

凝胶过滤色谱技术是利用分子筛原理,根据大小分子在不同的时间流出从而达到分离的目的[54]。被分离的咸味肽组分随着流动相在不同时间流出,分子越大越易收集,从而实现咸味肽的分离。Xia等[55]通过凝胶过滤色谱技术从秀珍菇蛋白水解物中成功分离γ-谷酰胺肽,结果证明,γ-谷酰胺肽可以显著地增加咸味和鲜味。

5.1.3 高效液相色谱技术

高效液相色谱技术是植物源咸味肽分离纯化最常用的技术之一。其原理是利用物质在两相中的分配系数差异,随着流动相的洗脱,不同性质的组分在不同时间流出,进而达到分离纯化的目的[56]。此技术因其分离范围广、分离效果好及选择性好等优势被广泛应用于咸味肽分离纯化中。熊建等[57]使用高效液相色谱技术对酵母源咸味肽进行相对分子量测定,结果表明,酵母抽提物中<1 kDa肽段的咸味肽显著提升咸味和咸味。

5.2 植物源咸味肽的鉴定技术

由于咸味肽已成为国内外的研究热点,为促进咸味肽的发展,越来越多的鉴定方法应用于咸味肽中。目前主要的鉴定方法有质谱法、傅里叶变换红外光谱技术、核磁共振技术及分子对接技术等。

5.2.1 质谱法

质谱法是利用磁场和电场将运动中的离子按照其质荷比分离后进行鉴定的方法[58]。因为此方法具有高特异性、灵敏度、鉴定速度快及操作简便等优点,已广泛应用在咸味肽氨基酸序列和相对分子质量鉴定中。利用液相色谱-质谱技术对以大豆为原料的发酵食品中的咸味肽进行定性和定量分析,研究结果表明酱油及大酱等大豆发酵食品中咸味肽的含量最高可达620 μg/g[27]。

5.2.2 傅里叶变换红外光谱技术

傅里叶变换红外光谱技术利用红外吸收光谱的谱峰位置来鉴定咸味肽,可以根据咸味肽不同结构产生不同的特征吸收带,以此确定咸味肽的二级结构[59]。利用傅里叶变换红外光谱技术成功鉴别出咸味肽的二级结构[60]。傅里叶变换红外光谱技术具有成本低、鉴定损失少、制样简单等优点,应用于鉴定咸味肽。

5.2.3 核磁共振技术

随着核磁共振技术的广泛应用,该技术已经成为蛋白多肽分析的主要技术之一[61]。已有报道利用核磁共振技术可以成功鉴定出多肽的结构[62]。目前,核磁共振技术已逐渐成为蛋白质多肽鉴定的主要技术之一,未来此技术可以应用与鉴定咸味肽的氨基酸序列和咸味肽混合物中各组分的含量的测定中。

5.2.4 分子对接技术

分子对接技术是呈味肽与受体蛋白进行特异性结合,进而识别出咸味肽氨基酸的序列,是一种快速且准确的新型鉴定技术[63]。目前,已经有T1R1/T1R3[64]及TMC4[65]等受体应用于咸味肽鉴定。Shan等[66]将酵母抽提物与T1R1/T1R3进行特异性结合,结果表明,KLLLLPKP、GGISTGNLN、LVKGGLIP和SSAVK具有咸味及咸味增强作用,其中GGISTGNLN的咸味阈值为157.47 mg/L。Shen等[67]利用TMC4对酵母抽提物中的咸味肽进行鉴定,进一步确定PN、NSE、NE、SPE为咸味肽。综上所述,利用受体蛋白可以大大提高咸味肽的可识别性,作为一种新型技术可以进一步提高咸味肽的开发及应用。

6. 植物源咸味肽的应用

植物源咸味肽作为咸味肽中的一种,不仅可以增强咸味感知,还具有一定的功能特性,效果优于非钠盐和风味改良剂。随着咸味肽的不断发展,目前已经应用在咸味香精、增咸烹饪盐及咸味增强剂等方面。

6.1 咸味香精

自20世纪80年代开始,我国咸味香精的研究已经过快速发展,目前在咸味香精领域已经处于世界前列[68]。目前,利用美拉德反应制备咸味香精已成为研究重点,其制备的咸味香精与调制香精相比,具有香气饱满及口感细腻等优点。咸味香精是植物蛋白酶解后产生的咸味肽与还原糖的美拉德反应产物。以大豆粕酶解液为原料,通过美拉德反应制备咸味香精,并利用高效液相色谱和气相色谱-质谱对咸味香精进行分析,检测出癸醛、2-癸酮、2-己基呋喃等物质,对肉香味的生成具有重要作用[69]。

6.2 增咸烹饪盐

为响应国家低钠减盐的号召,利用咸味肽可以增强咸味的特点开发的增咸烹饪盐已经成为了一种新的趋势。咸味肽可以提高食用盐的咸度,因此可以减少食盐中的钠含量,进而减少因过度摄入钠离子导致的高血压等心血管疾病。当前已有产品将酵母源咸味肽、水果有机酸按照一定比例加入精制食盐中,其咸度在精制食盐的基础上提高30%,做到真正的减盐不减咸[70]。

6.3 咸味增强剂

咸味增强剂是利用酶解技术制备的具有咸鲜风味,并且具有营养保健的功能,可用于开发功能性食品。王欣等[71]利用0.1%的木瓜蛋白酶对哈氏仿对虾蛋白进行酶解,得到的咸味肽咸度能将10 mmol/L提高到55 mmol/L。同时也有研究使用木瓜蛋白酶酶解淘汰蛋鸡来获得咸味肽,结果表明,咸味肽可以将50 mmol/L NaCl的咸度提高26.2%[72]。

7. 结论与展望

咸味肽作为具有一定的增咸、增鲜作用的天然咸味剂,在响应国家低钠减盐号召的同时,也满足消费者对天然产品的需求,因此开发咸味肽产品,受到了众多消费者的欢迎。我国作为农业大国,拥有丰富的农业资源,但对植物源咸味肽的探究相对较少。目前,关于植物源咸味肽的制备及应用过程中需要解决以下问题:a.目前对于植物源咸味肽的呈味机理、构效关系、制备鉴定及应用方面仍需进一步深入;b.如何基于鉴定技术客观反映不同制备方法产出的植物源咸味肽的呈味效果;c.目前制备植物源咸味肽的成本较高,应探索出更简便、高效的制备技术。植物源咸味肽不仅可以降低人体钠离子的摄入量,而且还具有一定的咸度,可以在一定条件下起到代替食用盐的作用,同时可以降低人体高血压等心血管疾病的发病率,植物源咸味肽的开发与应用具有广阔的前景。

-

表 1 咸味肽来源与结构式

Table 1 Origin and structural formula of salty peptides

类型 来源 咸味肽序列 参考文献 咸味二肽 大豆种子蛋白 Glu-Tyr,Glu-Phe [24] 大豆蛋白 Val-Gly [25] 大豆蛋白 Glu-Tyr,Glu-Phe [26] 豆瓣酱提取物 Glu-His,Glu-Trp,Glu-Leu,Glu-Met,Glu-Val,Glu-Gln,Glu-Phe [27] 味增提取物 Glu-Val [28] 可可豆蛋白 Tyr-Val [29] 咸味多肽 大豆蛋白 Glu-Val-Gly [25] 酱油提取物 Ser-Pro-Gln,Gln-Gly-Ile,His-Asn-Pro,Lys-Gly-Cys [30] 酱油提取物 Gly-Gly-Gly-Gly,Glu-Gln-Gln-Gln-Gln [31] 酱油提取物 Glu-Ala-Gly-Ile-Gln [32] -

[1] 张康逸, 屈凌波, 温青玉, 等. 咸味肽的制备技术研究进展[J]. 中国调味品,2022,47(6):204−211. [ZHANG K Y, QU L B, WEN Q Y, et al. Research progress on the preparation technology of salty peptides[J]. China Condiment,2022,47(6):204−211. ZHANG K Y, QU L B, WEN Q Y, et al. Research progress on the preparation technology of salty peptides[J]. China Condiment, 2022, 47(6): 204-211.

[2] HE F J, TAN M, MA Y, et al. Salt reduction to prevent hypertension and cardiovascular disease: JACC state-of-the-art review[J]. Journal of the American College of Cardiology,2020,75(6):632−647. doi: 10.1016/j.jacc.2019.11.055

[3] 张杰, 赵志峰, 郝罗, 等. 减盐策略及低钠盐研究进展[J]. 中国调味品,2021,46(3):179−184. [ZHANG J, ZHAO Z F, HAO L, et al. Research progress of salt reduction measures and low-sodium salt[J]. China Condiment,2021,46(3):179−184. doi: 10.3969/j.issn.1000-9973.2021.03.037 ZHANG J, ZHAO Z F, HAO L, et al. Research progress of salt reduction measures and low-sodium salt[J]. China Condiment, 2021, 46(3): 179-184. doi: 10.3969/j.issn.1000-9973.2021.03.037

[4] 张莹, 张一凡, 王世博, 等. 加工肉制品适用风味代盐剂的配方设计与优化[J]. 中国农业大学学报,2021,26(7):124−134. [ZHANG Y, ZHANG Y F, WANG S B, et al. Optimization and formulation design of flavor salt replacement for processed meat[J]. Journal of China Agricultural University,2021,26(7):124−134. ZHANG Y, ZHANG Y F, WANG S B, et al. Optimization and formulation design of flavor salt replacement for processed meat[J]. Journal of China Agricultural University, 2021, 26(7): 124-134.

[5] 陕怡萌, 蒲丹丹, 张玉玉, 等. 食品减盐方法研究进展[J]. 食品科学,2022,43(13):267−275. [SHAN Y M, PU D D, ZHANG Y Y, et al. A review of methods for salt reduction in foods[J]. Food Science,2022,43(13):267−275. SHAN Y M, PU D D, ZHANG Y Y, et al. A review of methods for salt reduction in foods[J]. Food Science, 2022, 43(13): 267-275.

[6] NURMILAH S, CAHYANA Y, UTAMA G L, et al. Strategies to reduce salt content and its effect on food characteristics and acceptance: A review[J]. Foods (Basel, Switzerland),2022,11(19):3120.

[7] LU J, CAO Y, PAN Y, et al. Sensory-guided identification and characterization of Kokumi-tasting compounds in green tea (Camellia sinensis L. )[J]. Molecules,2022,27(17):5677. doi: 10.3390/molecules27175677

[8] 曹清明, 王蔚婕, 张琳, 等. 中国居民平衡膳食模式的践行——《中国居民膳食指南(2022)》解读[J]. 食品与机械,2022,38(6):22−29. [CAO Q M, WANG W J, ZHANG L, et, al. The practice of balanced diet model for Chinese residents: Interpretation of dietary guidelines for Chinese residents (2022)[J]. Food & Machinery,2022,38(6):22−29. CAO Q M, WANG W J, ZHANG L, et, al. The practice of balanced diet model for Chinese residents: Interpretation of dietary guidelines for Chinese residents (2022)[J]. Food & Machinery, 2022, 38(6): 22-29.

[9] 孙宁玲, 姜一农, 王鸿懿, 等. 我国高血压患者的钠盐摄入现状[J]. 中华高血压杂志,2020,28(11):1025−1030. [SUN N L, JIANG Y N, WANG H Y, et al. The status of sodium intake in patients with hypertension in China[J]. Chinese Journal of Hypertension,2020,28(11):1025−1030. SUN N L, JIANG Y N, WANG H Y, et al. The status of sodium intake in patients with hypertension in China[J]. Chinese Journal of Hypertension, 2020, 28(11): 1025-1030.

[10] TADA M, SHINODA I, OKAI H. L-ornithyltaurine, a new salty peptide[J]. Journal of Agricultural and Food Chemistry,1984,32(5):992−996. doi: 10.1021/jf00125a009

[11] ZHAO J, LIAO S, BI X, et al. Isolation, identification and characterization of taste peptides from fermented broad bean paste[J]. Food & Function,2022,13(16):8730−8740.

[12] 杨文君, 段杉, 崔春. 豌豆蛋白深度酶解制备咸味肽的研究[J]. 中国调味品,2021,46(8):1−5. [YANG W J, DUAN S, CUI C. Study on preparation of salty peptides by deep enzymatic hydrolysis of pea protein[J]. China Condiment,2021,46(8):1−5. YANG W J, DUAN S, CUI C. Study on preparation of salty peptides by deep enzymatic hydrolysis of pea protein[J]. China Condiment, 2021, 46(8): 1-5.

[13] CHEN Y P, WANG M, BLANK I, et al. Saltiness-enhancing peptides isolated from the Chinese commercial fermented soybean curds with potential applications in salt reduction[J]. Journal of Agricultural and Food Chemistry,2021,69(35):10272−10280. doi: 10.1021/acs.jafc.1c03431

[14] 党亚丽, 张中健, 闫小伟, 等. 巴马火腿酶解物中呈味肽的分离纯化及其结构研究[J]. 食品科学,2010,31(13):127−131. [DANG Y L, ZHANG Z J, YAN X W, et al. Isolation, purification and structural identification of flavor peptides from enzymolyzed Parma ham[J]. Food Science,2010,31(13):127−131. DANG Y L, ZHANG Z J, YAN X W, et al. Isolation, purification and structural identification of flavor peptides from enzymolyzed Parma ham[J]. Food Science, 2010, 31(13): 127-131.

[15] 彭增起, 张雅玮, 郭秀云. 一种多肽食盐替代物及其制备方法: 中国, 102224921B[P]. 2012-11-28 PENG Z Q, ZHANG Y W, GUO X Y. A polypeptide salt substitute and its preparation method: China, 102224921B[P]. 2012-11-28.

[16] LE B, YU B, AMIN M S, et al. Salt taste receptors and associated salty/salt taste-enhancing peptides: A comprehensive review of structure and function[J]. Trends in Food Science & Technology,2022,129:657−666.

[17] 宋金萍, 王松, 郭丽荣. 上皮细胞钠离子通道及其相关调控因素在盐敏感性高血压中的作用[J]. 中华高血压杂志,2019,27(1):20−24. [SONG J P, WANG S, GUO L R. The role of epithelial sodium channels and their associated regulators in salt-sensitive hypertension[J]. Chinese Journal of Hypertension,2019,27(1):20−24. SONG J P, WANG S, GUO L R. The role of epithelial sodium channels and their associated regulators in salt-sensitive hypertension[J]. Chinese Journal of Hypertension, 2019, 27(1): 20-24.

[18] 文海若, 霍桂桃, 张颖丽, 等. TRPV1通道作为高血压防治新靶点研究进展[J]. 中国药事,2019,33(3):317−322. [WEN H R, HUO G T, ZHANG Y L, et al. Research progress of the TRPV1 as a novel tarft of prevention and treatment for hypertension[J]. Chinese Pharmaceutical Affairs,2019,33(3):317−322. WEN H R, HUO G T, ZHANG Y L, et al. Research progress of the TRPV1 as a novel tarft of prevention and treatment for hypertension[J]. Chinese Pharmaceutical Affairs, 2019, 33(3): 317-322.

[19] ANAND D, HUMMLER E, RICKMAN O J. ENaC activation by proteases[J]. Acta Physiologica,2022,235(1):e13811.

[20] ROPER S D, CHAUDHARI N. Taste buds: Cells, signals and synapses[J]. Nature Reviews Neuroscience,2017,18(8):485−497. doi: 10.1038/nrn.2017.68

[21] NOMURA K, NAKANISHI M, ISHIDATE F, et al. All-electrical Ca2+-independent signal transduction mediates attractive sodium taste in taste buds[J]. Neuron,2020,106(5):816−829. doi: 10.1016/j.neuron.2020.03.006

[22] 刘平, 车振明, 张晓鸣. 大豆肽的美拉德反应产物在鸡汤中的应用[J]. 食品工业科技,2014,35(4):110−113,117. [LIU P, CHE Z M, ZHANG X M. Application of Maillard reaction products derived from soy peptides[J]. Science and Technology of Food Industry,2014,35(4):110−113,117. LIU P, CHE Z M, ZHANG X M. Application of Maillard reaction products derived from soy peptides[J]. Science and Technology of Food Industry, 2014, 35(4): 110-113, 117.

[23] ZHENG Y Y, TANG L, YU M G, et al. Fractionation and identification of salty peptides from yeast extract[J]. Journal of Food Science and Technology,2021,58(3):1199−1208. doi: 10.1007/s13197-020-04836-1

[24] SHIBATA M, HIROTSUKA M, MIZUTANI Y, et al. Isolation and characterization of key contributors to the “kokumi” taste in soybean seeds[J]. Bioscience, Biotechnology, and Biochemistry,2017,81(11):2168−2177. doi: 10.1080/09168451.2017.1372179

[25] SUZUKI H, NAKAFUJI Y, TAMURA T. New method to produce Kokumi seasoning from protein hydrolysates using bacterial enzymes[J]. Journal of Agricultural and Food Chemistry,2017,65(48):10514−10519. doi: 10.1021/acs.jafc.7b03690

[26] SHIBATA M, HIROTSUKA M, MIZUTANI Y, et al. Diversity of γ-glutamyl peptides and oligosaccharides, the “kokumi” taste enhancers, in seeds from soybean mini core collections[J]. Bioscience, Biotechnology, and Biochemistry,2018,82(3):507−514. doi: 10.1080/09168451.2018.1436960

[27] KIM H J, LEE D Y, LEE I. Quantitative determination of kokumi compounds, γ-glutamyl peptides, in Korean traditional fermented foods, ganjang and doenjang, by LC-MS/MS[J]. Food Science and Biotechnology,2021,30(11):1465−1470. doi: 10.1007/s10068-021-00993-x

[28] HO T V, SUZUKI H. Increase of “Umami” and “Kokumi” compounds in Miso, fermented soybeans, by the addition of bacterial γ-glutamyltranspeptidase[J]. International Journal of Food Studies,2013,2(1):39−47.

[29] SALGER M, STARK T D, HOFMANN T. Taste modulating peptides from overfermented Cocoa beans[J]. Journal of Agricultural and Food Chemistry,2019,67(15):4311−4320. doi: 10.1021/acs.jafc.9b00905

[30] 陈嘉辉. 酱油中呈味肽的分离鉴定及呈味特性的对比分析[D]. 广州: 华南理工大学, 2018 CHEN J H. The purification and identification of flavor peptides from soy sauce and the comparison of its flavor characteristics[D]. Guangzhou: South China University of Technology, 2018.

[31] ZHUANG M Z, LIN L Z, ZHAO M M, et al. Sequence, taste and umami-enhancing effect of the peptides separated from soy sauce[J]. Food Chemistry,2016,206:174−181. doi: 10.1016/j.foodchem.2016.03.058

[32] 庄明珠. 酱油鲜味肽的分离纯化鉴定及呈味特性研究[D]. 广州: 华南理工大学, 2015 ZHUANG M Z. The purification and identification of umami peptides from soy sauce and the study of its taste characteristic[D]. Guangzhou: South China University of Technology, 2015.

[33] SELAMASSAKUL O, LAOHAKUNJIT N, KERDCHOECHUEN O, et al. Bioactive peptides from brown rice protein hydrolyzed by bromelain: Relationship between biofunctional activities and flavor characteristics[J]. Journal of Food Science,2020,85(3):707−717. doi: 10.1111/1750-3841.15052

[34] SONG X L, SHI Z H, LI X F, et al. Fate of proteins of waste activated sludge during thermal alkali pretreatment in terms of sludge protein recovery[J]. Frontiers of Environmental Science & Engineering,2019,13(2):1−9.

[35] DA SILVA R R. Enzymatic hydrolysis of non-animal proteins for improving nutritional and sensory properties of foods[J]. Journal of Food Biochemistry,2021,45(9):e13891.

[36] EBAID R, WANG H C, SHA C, et al. Recent trends in hyperthermophilic enzymes production and future perspectives for biofuel industry: A critical review[J]. Journal of Cleaner Production,2019,238:117925. doi: 10.1016/j.jclepro.2019.117925

[37] CHAI K F, VOO A Y H, CHEN W N. Bioactive peptides from food fermentation: A comprehensive review of their sources, bioactivities, applications, and future development[J]. Comprehensive Reviews in Food Science and Food Safety,2020,19(6):3825−3885. doi: 10.1111/1541-4337.12651

[38] 于铁妹. 肽类合成方法研究进展[J]. 广州化工,2020,48(16):12−14. [YU T M. Research progress on the synthesis of peptides[J]. Guangzhou Chemical Industry,2020,48(16):12−14. YU T M. Research progress on the synthesis of peptides[J]. Guangzhou Chemical Industry, 2020, 48(16): 12-14.

[39] 潘丽军, 张丽, 钟昔阳, 等. 双酶分步水解法制备谷氨酰胺活性肽的研究[J]. 食品工业科技,2009,30(5):184−187. [PAN L J, ZHANG L, ZHONG X Y, et al. Study on preparation of glutamine-bioactive peptides by teo enzyme-hydrolyzed wheat protein[J]. Science and Technology of Food Industry,2009,30(5):184−187. PAN L J, ZHANG L, ZHONG X Y, et al. Study on preparation of glutamine-bioactive peptides by teo enzyme-hydrolyzed wheat protein[J]. Science and Technology of Food Industry, 2009, 30(5): 184-187.

[40] JEON S Y, LEE Y M, KIM S S, et al. Effect of added hydrolyzed vegetable proteins on consumers' response for Doenjang (Korean traditional fermented soybean paste) soup[J]. Food Science and Biotechnology,2020,29(1):45−53. doi: 10.1007/s10068-019-00646-0

[41] ZHAO Y Q, ZHAO X, SUN D X-WATERHOUSE, et al. Two-stage selective enzymatic hydrolysis generates protein hydrolysates rich in Asn-Pro and Ala-His for enhancing taste attributes of soy sauce[J]. Food Chemistry,2021,345:128803. doi: 10.1016/j.foodchem.2020.128803

[42] YAN F, CUI H P, ZHANG Q, et al. Small peptides hydrolyzed from pea protein and their Maillard reaction products as taste modifiers: Saltiness, umami, and Kokumi enhancement[J]. Food and Bioprocess Technology,2021,14(6):1132−1141. doi: 10.1007/s11947-021-02630-1

[43] LI L J, TAN W S, LI W J, et al. Citrus taste modification potentials by genetic engineering[J]. International Journal of Molecular Sciences,2019,20(24):6194. doi: 10.3390/ijms20246194

[44] 宋明媚, 鞠培培, 曹建军, 等. 化学法合成RGD三肽的研究[J]. 生物加工过程,2005(2):23−26. [SONG M M, JU P P, CAO J J, et al. Study on the synthesis of RGD tripeptide by the chemical method[J]. Chinese Journal of Bioprocess Engineering,2005(2):23−26. SONG M M, JU P P, CAO J J, et al. Study on the synthesis of RGD tripeptide by the chemical method[J]. Chinese Journal of Bioprocess Engineering, 2005, 2: 23-26.

[45] BABINI E, TANEYO-SAA D L, TASSONI A, et al. Microbial fermentation of industrial rice-starch byproduct as valuable source of peptide fractions with health-related activity[J]. Microorganisms,2020,8(7):986. doi: 10.3390/microorganisms8070986

[46] SCHÖWE M J, KEIPER O, UNVERZAGT C, et al. A tripeptide approach to the solid-phase synthesis of peptide thioacids and N-glycopeptides[J]. Chemistry: A European Journal,2019,25(69):15759−15764. doi: 10.1002/chem.201904688

[47] LI H D, REN J, LI J Y, et al. Greener liquid-phase synthesis and the ACE inhibitory structure-activity relationship of an anti-SARS octapeptide[J]. Organic & Biomolecular Chemistry,2020,18(41):8433−8442.

[48] 郑龙, 田佳鑫, 张泽鹏, 等. 多肽药物制备工艺研究进展[J]. 化工学报,2021,72(7):3538−3550. [ZHENG L, TIAN J X, ZHANG Z P, et al. Progress on pharmaceutical engineering of peptide-based drugs[J]. CIESC Journal,2021,72(7):3538−3550. ZHENG L, TIAN J X, ZHANG Z P, et al. Progress on pharmaceutical engineering of peptide-based drugs[J]. CIESC Journal, 2021, 72(7): 3538-3550.

[49] 周佳琪, 马春燕, 李晓晖. 多肽类ACE抑制剂的设计合成及生物活性[J]. 食品工业科技,2022,43(23):26−34. [ZHOU J Q, MA C Y, LI X H. Design, synthesis and bioactivity of polypeptide ACE inhibitors[J]. Science and Technology of Food Industry,2022,43(23):26−34. ZHOU J Q, MA C Y, LI X H. Design, synthesis and bioactivity of polypeptide ACE inhibitors[J]. Science and Technology of Food Industry, 2022, 43(23): 26-34.

[50] FENG T, WU Y, ZHANG Z W, et al. Purification, identification, and sensory evaluation of Kokumi peptides from Agaricus bisporus mushroom[J]. Foods,2019,8(2):43. doi: 10.3390/foods8020043

[51] 于群. 超滤技术在蛋白质分离纯化中的应用研究[J]. 当代化工研究,2020(22):137−138. [YU Q. Application of ultrafiltration technology in protein separation and purification[J]. Modern Chemical Research,2020(22):137−138. YU Q. Application of ultrafiltration technology in protein separation and purification[J]. Modern Chemical Research, 2020, 22: 137-138.

[52] SRIDHAR K, INBARAJ B S, CHEN B H. Recent developments on production, purification and biological activity of marine peptides[J]. Food Research International,2021,147:110468. doi: 10.1016/j.foodres.2021.110468

[53] KONG Y, ZHANG L L, ZHAO J, et al. Isolation and identification of the umami peptides from shiitake mushroom by consecutive chromatography and LC-Q-TOF-MS[J]. Food Research International,2019,121:463−470. doi: 10.1016/j.foodres.2018.11.060

[54] ZHANG J N, ZHAO M M, SU G W, et al. Identification and taste characteristics of novel umami and umami-enhancing peptides separated from peanut protein isolate hydrolysate by consecutive chromatography and UPLC-ESI-QTOF-MS/MS[J]. Food Chemistry,2019,278(25):674−682. doi: 10.1016/j.foodchem.2018.11.114

[55] XIA X Z, FU Y, MA L, et al. Protein hydrolysates from Pleurotus geesteranus modified by Bacillus amyloliquefaciens γ-glutamyl transpeptidase exhibit a remarkable taste-enhancing effect[J]. Journal of Agricultural and Food Chemistry,2022,70(38):12143−12155. doi: 10.1021/acs.jafc.2c03941

[56] 杨彩霞, 吴金梅, 何涛. 反相高效液相色谱法测定枯草菌肽的含量及纯度[J]. 安徽农业科学,2022,50(2):206−210. [YANG C X, WU J M, HE T. Determination of the content and purity of sublancin by reversed-phase high performance liquid chromatography[J]. Journal of Anhui Agricultural Sciences,2022,50(2):206−210. YANG C X, WU J M, HE T. Determination of the content and purity of sublancin by reversed-phase high performance liquid chromatography[J]. Journal of Anhui Agricultural Sciences, 2022, 50(2): 206-210.

[57] 熊建, 覃先武, 李丽娜, 等. 酵母抽提物减盐功能及在高汤调味粉中应用研究[J]. 食品工业科技,2022,43(19):307−314. [XIONG J, QIN X W, LI L N, et al. Study on salt reduction of yeast extract and its application in broth powder[J]. Science and Technology of Food Industry,2022,43(19):307−314. XIONG J, QIN X W, LI L N, et al. Study on salt reduction of yeast extract and its application in broth powder[J]. Science and Technology of Food Industry, 2022, 43(19): 307-314.

[58] ZHAO P Y, WANG Q, KAUR M, et al. Absolute quantitation of proteins by coulometric mass spectrometry[J]. Analytical Chemistry,2020,92(11):7877−7883. doi: 10.1021/acs.analchem.0c01151

[59] HAO J W, CHEN N D, FU X C, et al. Predicting the contents of polysaccharides and its monosugars in Dendrobium huoshanense by partial least squares regression model using attenuated total reflectance Fourier transform infrared spectroscopy[J]. Spectroscopy Letters,2019,52(5):297−305. doi: 10.1080/00387010.2019.1630445

[60] MALIN E L, ALAIMO M H, BROWN E M, et al. Solution structures of casein peptides: NMR, FTIR, CD, and molecular modeling studies of alphas1-casein, 1-23[J]. Journal of Protein Chemistry,2001,20(5):391−404. doi: 10.1023/A:1012232804665

[61] HAUSER A, POULOU E, MÜLLER F, et al. Synthesis and evaluation of non-hydrolyzable phospho-lysine peptide mimics[J]. Chemistry:A European Journal,2021,27(7):2326−2331. doi: 10.1002/chem.202003947

[62] BAEK M-H, KAMIYA M, KUSHIBIKI T, et al. Lipopolysaccharide-bound structure of the antimicrobial peptide cecropin P1 determined by nuclear magnetic resonance spectroscopy: LPS-Bound Structure of CP1[J]. Journal of Peptide Science,2016,22(4):214−221. doi: 10.1002/psc.2865

[63] AGRAWAL P, SINGH H, SRIVASTAVA H K, et al. Benchmarking of different molecular docking methods for protein-peptide docking[J]. BMC Bioinformatics,2019,19(S13):426. doi: 10.1186/s12859-018-2449-y

[64] DANG Y L, HAO L, CAO J X, et al. Molecular docking and simulation of the synergistic effect between umami peptides, monosodium glutamate and taste receptor T1R1/T1R3[J]. Food Chemistry,2019,271:697−706. doi: 10.1016/j.foodchem.2018.08.001

[65] KASAHARA Y, NARUKAWA M, ISHIMARU Y, et al. TMC4 is a novel chloride channel involved in high-concentration salt taste sensation[J]. The Journal of Physiological Sciences,2021,71(1):23. doi: 10.1186/s12576-021-00807-z

[66] SHAN Y M, PU D D, ZHANG J C, et al. Decoding of the saltiness enhancement taste peptides from the yeast extract and molecular docking to the taste receptor T1R1/T1R3[J]. Journal of Agricultural and Food Chemistry,2022,70(47):14898−14906. doi: 10.1021/acs.jafc.2c06237

[67] SHEN D Y, PAN F, YANG Z C, et al. Identification of novel saltiness-enhancing peptides from yeast extract and their mechanism of action for transmembrane channel-like 4 (TMC4) protein through experimental and integrated computational modeling[J]. Food Chemistry,2022,388(15):132993. doi: 10.1016/j.foodchem.2022.132993

[68] 郑家伦, 李晨, 陆利霞, 等. 美拉德反应制备咸味香精研究进展[J]. 中国调味品,2016,41(12):129−133. [ZHENG J L, LI C, LU L X, et al. Research progress of savory flavoring prepared by Maillard reaction[J]. China Condiment,2016,41(12):129−133. doi: 10.3969/j.issn.1000-9973.2016.12.030 ZHENG J L, LI C, LU L X, et al. Research progress of savory flavoring prepared by Maillard reaction[J]. China Condiment, 2016, 41(12): 129-133. doi: 10.3969/j.issn.1000-9973.2016.12.030

[69] 郑家伦, 李晨, 陆利霞, 等. 基于大豆粕酶解物美拉德反应制备咸味香精的研究[J]. 中国调味品,2017,42(10):4−10. [ZHENG J L, LI C, LU L X, et al. Research on savory flavoring prepared by Maillard reaction based on soybean meal hydrolysate[J]. China Condiment,2017,42(10):4−10. ZHENG J L, LI C, LU L X, et al. Research on savory flavoring prepared by Maillard reaction based on soybean meal hydrolysate[J]. China Condiment, 2017, 42(10): 4-10.

[70] 迟韵, 陈虎, 陈留平, 等. 增咸烹饪盐的减钠研究[J]. 盐科学与化工,2020,49(11):15−18. [CHI Y, CHEN H, CHEN L P, et al. Research of reducing sodium on saltiness-enhanced cooking salt[J]. Journal of Salt Science and Chemical Industry,2020,49(11):15−18. CHI Y, CHEN H, CHEN L P, et al. Research of reducing sodium on saltiness-enhanced cooking salt[J]. Journal of Salt Science and Chemical Industry, 2020, 49(11): 15-18.

[71] 王欣, 安灿, 陈美龄, 等. 酶水解哈氏仿对虾蛋白提高咸味的研究[J]. 中国调味品,2017,42(5):12−16. [WANG X, AN C, CHEN M L, et al. Enzymatic hydrolysis of Paeapenaeopsis hardwickii (Miers) protein for enhancing saltiness[J]. China Condiment,2017,42(5):12−16. WANG X, AN C, CHEN M L, et al. Enzymatic hydrolysis of Paeapenaeopsis hardwickii (Miers) protein for enhancing saltiness[J]. China Condiment, 2017, 42(5): 12-16.

[72] 陈瑞霞, 孙思远, 相悦, 等. 以淘汰蛋鸡为原料利用蛋白酶解技术制备咸味增强肽[J]. 食品与发酵工业,2020,46(1):166−171. [CHEN R X, SUN S Y, XIANG Y, et al. Optimization of enzymatic hydrolysis for rejected hen protein for salt-enhanced peptides preparation[J]. Food and Fermentation Industries,2020,46(1):166−171. CHEN R X, SHUN S Y, XIANG Y, et al. Optimization of enzymatic hydrolysis for rejected hen protein for salt-enhanced peptides preparation[J]. Food and Fermentation Industries, 2020, 46(1): 166-171.

下载:

下载:

下载:

下载: